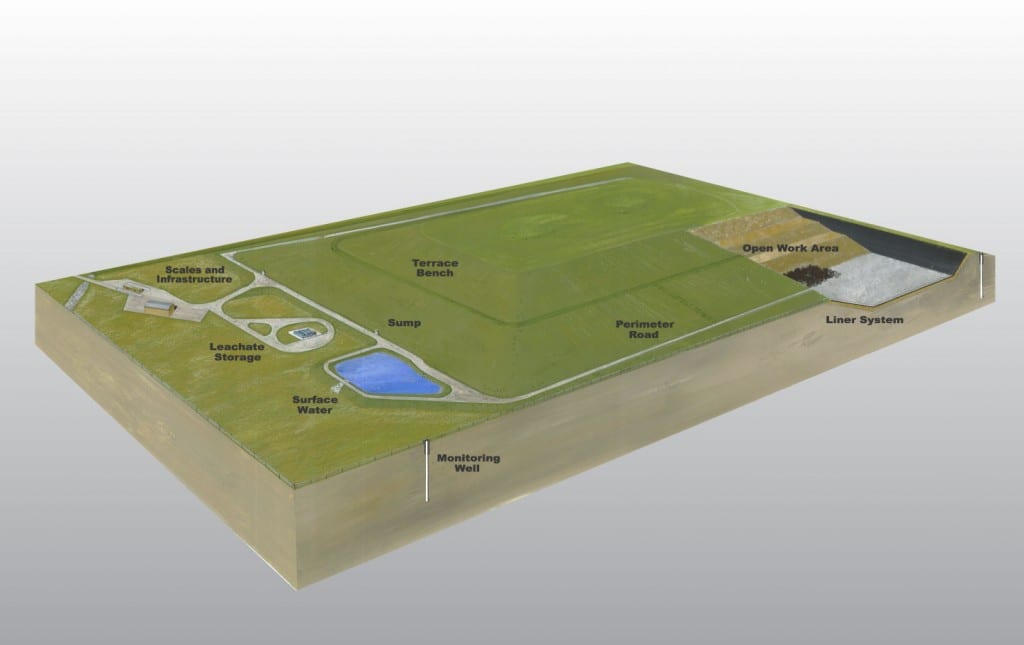

Facility Details

Waste is placed into lined cells, and compacted to the smallest practical volume using equipment such as bulldozers. When the waste height reaches between 4 and 6 feet (a “lift”), a layer of cover soil will be placed on top of the lift to reduce rainfall infiltration. The cells will be developed sequentially to minimize the area open at any one time. Any water that touches the waste will be handled as a waste product and disposed of in strict accordance with state regulation.

All waste received by PW will only be accepted if pre-approved in accordance with our Waste Acceptance Plan. This Plan requires careful evaluation and recommendation by CDPHE, and permitting by Weld County. As proposed, it will be routinely reviewed and updated using site-specific data generated from the incoming waste streams.

In addition to waste sampling, PW will track and record each load accepted from our customers. PW is required to provide safety training for all of our personnel.

Acceptable Waste Guidelines

- Only waste generated by the exploration or production of oil & gas will be received at the landfill for disposal.

- PW is prohibited from accepting hazardous wastes and disposing of wastes that contain free liquids.

- PW will accept exploration wastes such as drill cuttings, muds, and other solids associated with drilling activities.

- PW will accept production wastes such as tank bottoms from reclaimers and injection well facilities.

- The accepted wastes may only contain very low concentrations of naturally occurring and technologically enhanced radioactive material.

Pawnee Waste’s innovative facility is designed to protect groundwater by the installation of a high-density polyethylene synthetic liner (60 mil HDPE), a geo-synthetic clay liner (GCL), a two-foot bentonite clay-enhanced soil liner (1×10 -7 cm/sec), and at least 20 feet of separation between the shallowest groundwater and waste.

PW will perform Electrical Leak Location (ELL) testing of its HDPE liner to ensure proper installation. ELL testing is required in other states and widely utilized because it is proven to be extremely effective in reducing the potential for liner leakage.

A comprehensive Monitoring Plan that strictly follows CDPHE requirements has already begun implementation and includes conducting routine groundwater monitoring of established monitoring wells located around the perimeter of the facility.

The facility will apply final cover soil in accordance with CDPHE standards that are designed to minimize penetration of rainfall into the waste long after the facility has been closed.

Financial instruments to cover the cost of closure and post-closure care are required prior to operation, and must be updated annually.

Pawnee Waste’s liner design provides multiple safeguards to protect the environment. We have chosen to exceed CDPHE requirements because we are dedicated to providing the highest level of long-term security for our customers and the public.

- Electrical Leak Location: This test, which is required in other states, uses advanced resistivity technology to identify liner pinholes, construction related damage or seams that may not be properly welded. It allows any liner defects to be mended before any waste is accepted.

- HDPE Liner: This type of liner has been proven worldwide to provide a high level of protection to groundwater resources, and is recognized as having the most robust properties to securely contain waste.

- GCL Layer: This geo-synthetic clay liner consists of a bentonite mat encased in geotextile. It is frequently used in connection with HDPE because of its self-healing properties.

- Bentonite-Native Soils Compacted Liner: Many landfills in Colorado are designed using native soils only. The addition of bentonite to the natural soils ensures that this liner layer will act as a low permeability barrier.

- In-Situ Soils: The design provides a minimum vertical separation of 20 feet between the bottom of the liner system and the level where groundwater is first encountered.

The facility is located in the heart of active drilling in the DJ Basin. It is located in Weld Count: Township 10 N, 61 W, Section 13. It is co-located on the same section as other industries supporting the energy industry.

Pawnee is the only landfill identified in Weld County as approved for the receipt of E&P TENORM wastes.

All E&P waste has the potential to contain concentrations of radionuclides above CDPHE administrative limits. Such wastes include:

- Filter socks

- Tank bottoms

- Horizontal drill cuttings generated from formations bearing NORM

- Filter press cake

- Waste pipe and flow line sections

- Residual materials dislodged during cleaning and maintenance activities on the following:

- Crude oil and natural gas pipelines, flow lines and connector pipes (pipe scale scraping/rattling/wire brushing)

- Natural Gas pigging wastes, scrubbers, compressors, reflux pumps, control valves and product lines

- Gas/oil separators

- Dehydration vessels

- Liquid natural gas (LNG) storage tanks

We recommend that generators of the wastes identified above by CDPHE obtain documentation from their select facility to ensure: (1) the disposal site is approved by the state and local governments for receipt of E&P waste with TENORM and, (2) that the facility accepts responsibility for wastes with agreed to radioactive materials as part of the disposal contract.

Facility Graphics